Omega Falling Film Chillers

The Omega Falling Film Chiller is a water cooler based on Pillow Plate technology. With the ice water at temperature (<0.5 °C) from a Falling Film Chiller you can cool large amounts of product in a short time. This (recirculating) water cooler, which cools the water at a constant temperature, is a suitable solution for the continuous cooling of your products.

Because every cooling requirement is different, our Falling Film Chillers are always custom-made. Together with our engineers, we calculate the best solution for you.

What is a Falling Film Chiller?

A Omega Falling Film Chiller are suitable for cooling water to a certain desired temperature. Ice water is used to cool large quantities of your product in a short amount of time, for example to blanch vegetables or to mix with concrete in prevention to dry quickly. Due to the open system it is also suitable for cooling contaminated liquids.

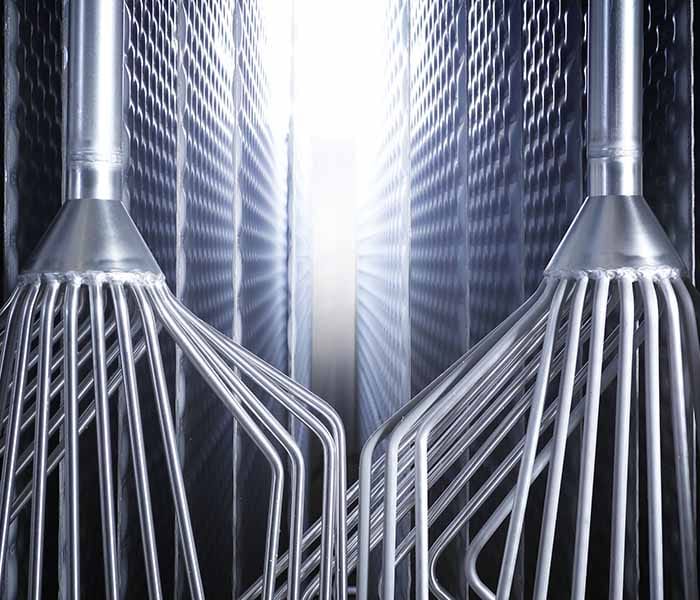

It’s also possible to recirculate the water and let Omega Pillow Plates cool the water down again to the right temperature. With this recirculating Falling Film Chiller your products are continuously cooled to an even temperature.

How does a Falling Film Chiller work?

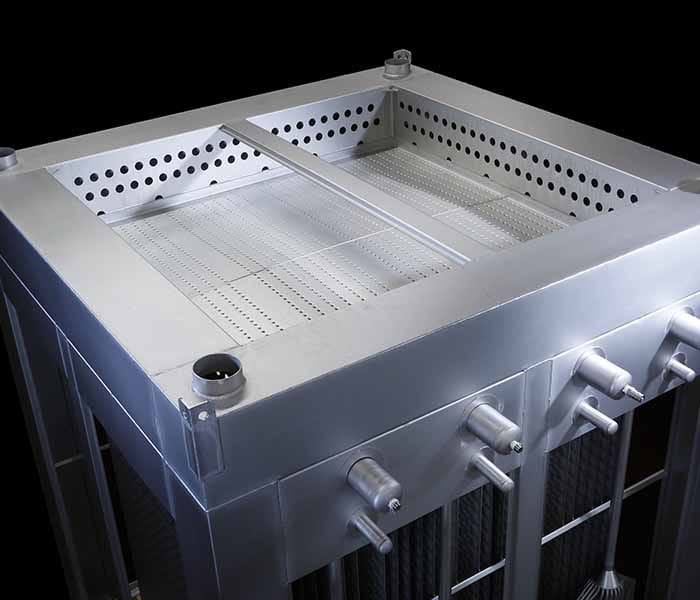

In the upper container of the appliance, the water will be divided into small holes to the double embossed Pillow Plates, hanging underneath. A thin layer of water falls over the plate and is cooled to the desired temperature. The water can be cooled to 0,5 °C with a Falling Film Chiller.

This cooled water is pumped into a container and distributed to the user(s), such as a plate heat exchanger or process tank.

The used water is collected in a reservoir and pumped back to the top of the Falling Film Chiller. The water is cooled again in the same way.

Advantages

- Efficient cooling to very low temperatures (<0,5 °C) without the risk of freezing

- Suitable for cooling down to 0,5°C without risk of damage due to ice

- Constant temperature of the chilled water

- Custom-made to your needs

- Easy to maintain open construction. Occasional cleaning with high pressure

- Full construction of stainless steel

- Can cool slightly polluted water (particles smaller than 8 mm)

- Capacities up to 2500 kW per unit

If you want to know more about the design, request additional information.