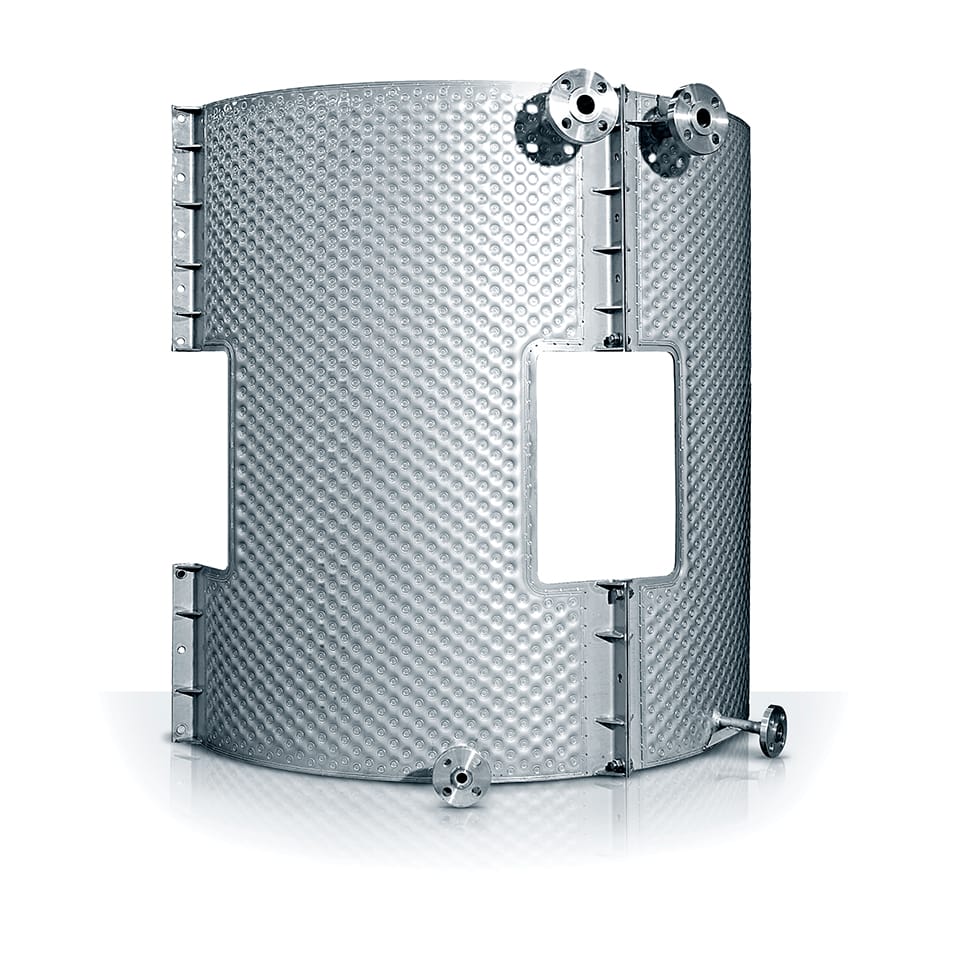

Clamp-on

Omega’s Clamp-on Pillow Plates are used by mounting onto existing applications to provide heating or cooling of the product inside the existing vessel. Clamp-on plates are available in either single or double embossed construction, they can be flat or in the rolled orientation for use on tanks. Rather than cooling an entire room of tanks or investing in newly fabricated tanks with build-in heat exchangers, a more cost effective solution can be obtained by installing Omega’s Tank Clamp-on Pillow Plates.

How does a Tank heating and cooling jacket work?

Based on your data, we calculate the required capacity to cool the existing tank or to heat it to the desired temperature.

Our tank clamp-on jackets are first welded as regular Pillow Plates, after which we roll and inflate them in the desired shape. You will receive the tank heating and cooling jacket completely finished with the right connections and drains. You only need to mount it on your tank. Our engineers will assist you with the assembly.

Double embossed tank clamp-on jacket

In most cases, Omega tank clamp-on jackets are double embossed. There are pillows on both sides of the jacket. By using heat conduction paste, the clamp-on jacket fits completely to your tank.

Single embossed tank clamp-on jacket

If you’d rather not want to work with this heat conduction paste, it is possible to opt for a single embossed clamp-on jacket.

Advantages

- A more cost efficient solution compared to building a new tank

- Usually no need for welding on the existing tank

- No need for welding on the existing tank

- The cooling or heating medium is physically separated from the application containing the product

- Design flexibility for proper placement on vessel

- Even and constant heating or cooling of the product

Application

All of our Clamp-on Pillow Plates are custom-made. Please consult an Omega IceHill Sales Engineer so we can discuss your requirements for cooling or heating and determine which solution is best suited for you. Below are some of the service medium and material options:

- Chemical industries where heat exchangers are interchangeable for potential standstill

- For cooling of existing dairy tanks

- For heating of seal, purge and flush drum of Heavy Vacuum Gas Oil (HVGO)

- For heating of transfer oil drum

- For heating of Acetic Acid

- For heating of Butyl Acrylate

- For heating of Polyethylene tanks

- For heating of existing screw conveyors

- For heating of Styrene butadiene tanks

If you want to know more about the design, request additional information