Pillow Plates

Pillow Plates are heat exchanger plates that can be used in many ways for the industrial cooling or heating of your products. As the developer of the laser welding machine for these Pillow Plates, Omega Thermo Products has an unprecedented amount of experience in manufacturing Pillow Plates.

These laser welded plates have endless applications in different industries. Omega Pillow Plates are used for vessels, for example for cooling milk, soft drinks, wine or beer. But also various other sectors use our plates. For example, the meat processing industry, the chemical industry and the pharmaceutical industry.

What is a Pillow Plate?

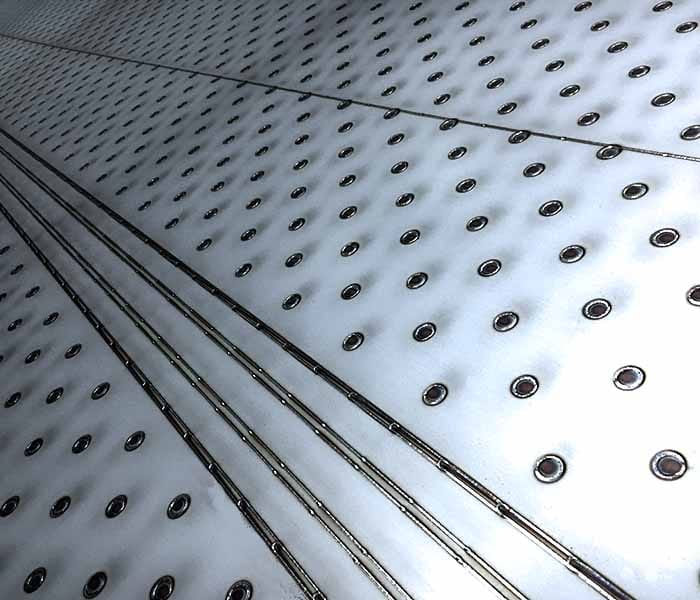

The Omega Pillow Plate consists of two stainless steel sheets that are laser welded together by welding a custom circle weld pattern. The outside perimeter of the Pillow Plate is fully laser welded to create a pressure boundary. At the edges of the Pillow Plate, a contour is welded to create a pressure-tight part.

The Pillow Plate is hydraulically inflated by using water through a hydrostatic pump. Hydraulically inflating will guarantee for a safe inflation process. Other inflation processes can be used depending on the application.

The inflation process pressurizes the two sheets which allows the material to deform, a cavity will be created for use of a heat transfer medium. The Omega Pillow Plate can be used with either liquids, steam or refrigerants.

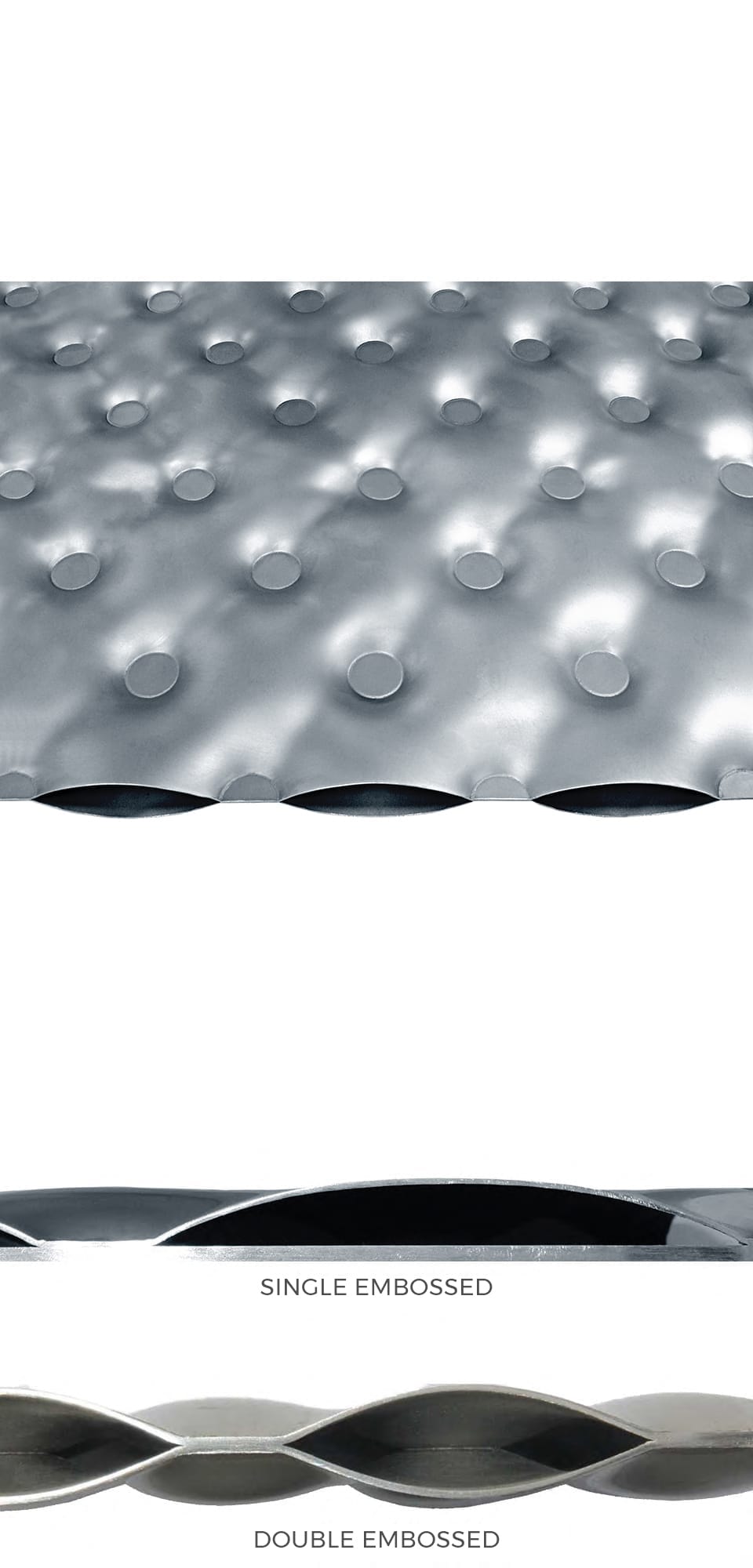

Design (single of double embossed)

A Pillow Plate design is always custom-made. At first we look at your desired application. Do you need a plate with pillows on one side and a smooth surface on the other (for example, applications for cooling milk tanks or heat or cool applications in food or the pharmaceutical industry), then choose a single embossed Pillow Plate. The flat product side of the single embossed heat exchanger are used for sanitary product applications. Due to the precise welding process we can guarantee that no heat tint will occur after welding, the material is welded with the protective PVC foil in place. Omega will supply detailed procedures on how to install connections and inflate the Pillow Plates.

Our experienced engineering team is available to assist on your first Pillow Plate inflation!

Double embossed Pillow Plates are plates that exists of two sheets with similar material thicknesses. This product will deform on both sides after inflation as no flat side is required for the application. The double embossed product is used for immersion applications, clamp-on applications, other process equipment like heat recover banks and refrigeration applications.

We also process these double embossed plates in our coolers, such as the Falling Film Chiller, Ice Bank, Ice Machine and Immersion Chillers.

Advantages

- Cost-effective due to low welding costs

- Thinner materials can be used, saving you on material costs

- Pillow Plates' welding pattern guarantees high turbulence and therefore creates high overall heat transfer coefficients

- Reduced deposition (algae, lime, etc.) due to this higher turbulence (less fouling)

- Due to the low volume in the plate, little cooling / heating fluid needs to be circulated. As a result, less pump capacity is required

- By working with laser welding machines that are CNC-programmed, all desired shapes, recesses, fastening points and connections are possible

We are pleased to help you with a heat transfer calculation!